DVERT® Technology

NOx reduction technology

NOx is produced when ambient oxygen and nitrogen react with each other in a high-temperature environment. Diesel engines operate with high compression ratios and lean fuel mixtures, resulting in an oxygen- and nitrogen-rich atmosphere within the combustion chamber that leads to formation of NOx.

Partial return of exhaust gases into the combustion chamber (exhaust gas recirculation, EGR) reduces the ratio of excess air, stabilizing and facilitating oxygen and nitrogen molecules to bond as NOx in a chemical reaction.

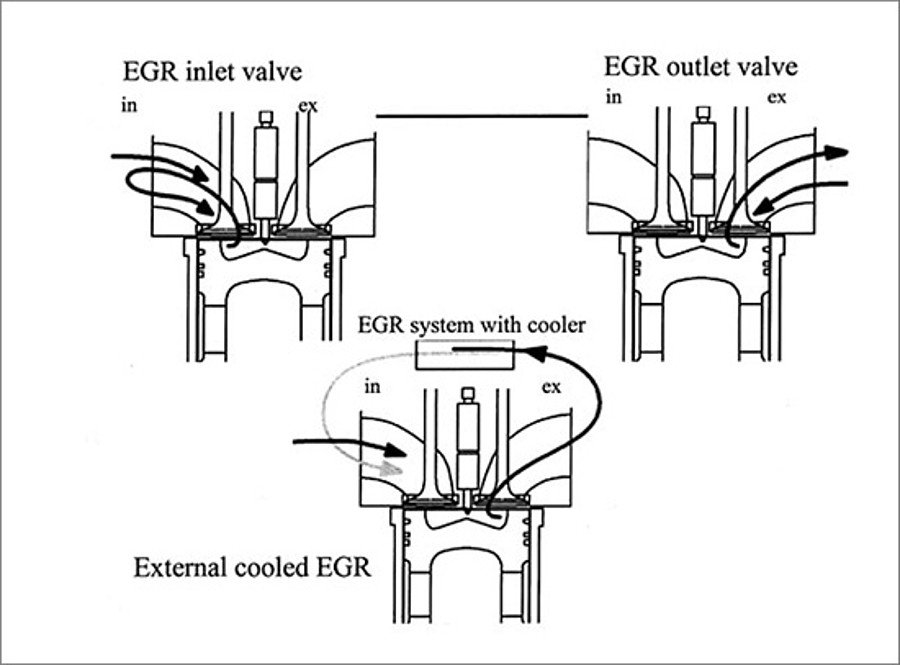

Exhaust gas recirculation can be achieved by multiple methods:

Internal EGR

The simplest means is either to open the outlet valve during aspiration stroke or the inlet valve during outlet stroke. Both methods can be implemented by simple camshaft modification, but with the disadvantage that camshafts cannot be deactivated. With this method, the EGR operates continuously, regardless of engine load and speed. Internal, uncontrolled EGR presents slight torque acceptance disadvantages at some engine operating points under certain optimized camshaft profiles.

Controlled internal EGR

Another EGR method is by electronic control of the outlet valve threshold. The outlet valve stroke for the EGR is hydraulically actuated by connection with the inlet cam. This connection can be broken by a solenoid valve which deactivates the EGR. One advantage is that this system is controlled by the engine management system without having the disadvantage of cooled external EGR, corrosive materials. Other advantages are improved driving dynamics and faster engine response. Controlled internal EGR is primarily used in high-performance equipment such as tractors, factory floor vehicles and building machinery.

Cooled EGR

A third EGR method is a defined amount of exhaust gas through an external cooler, then rerouted into the combustion system via a clack valve. This method is known as external, cooled EGR. External, cooled EGR provides higher power density and better torque control because the diverter valve can be controlled electronically by the engine management system (definition of the EGR amount). In-cylinder engine temperature is reduced by feeding back cooled exhaust gases, resulting in higher power density. The disadvantages of external, cooled EGR are increased cooling requirements and, significantly, the conversion of sulphur from diesel fuel into corrosive sulphuric acid. This is a particular reason why all manufacturers of high-performance diesel engines lobby the distribution of sulphur-free diesel fuel to accommodate this EGR method. DEUTZ uses especially suitable materials to avoid corrosion.

To purchase DEUTZ engines with DVERT hardware and software, contact your local DEUTZ distributor by clicking here.